Making and Designing of the Bongs the Preferred Way

A bong, commonly referred to as a water pipe, is a filtering mechanism most frequently used for cannabis smoking. You would approach the head shop or possibly the web retailer offering the most recent marijuana products. These glass artifacts are the work of accomplished craftspeople. Most people consider bong-related products to be works of art. People typically lack an understanding of the art of glassblowing. It’s interesting to learn how intricate and unique things are manufactured. You can explore the web or visit a bong website to find out more about the art. You’ll have a better idea of how bongs are manufactured after reading this.

Designing the Bongs with Sophistication

With the right deduction from several parameters, you will discover how are bongs made. Even in terms of sophistication, there is a basic difference between bongs and other popular glass smoking equipment. You would like the striking colors and complex patterns of the glass. Simply wonderful is the decoration. Clean and regular designs may be noticed on the bongs’ outside. Some components, including the optimum ice catcher and other design requirements, are also taken from other sections.

Artistic Sense in Making

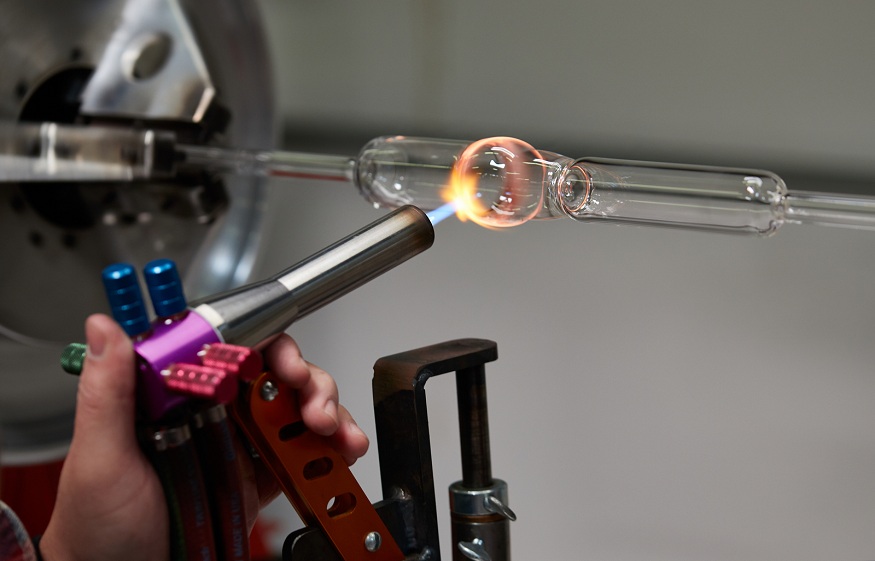

Even the bongs are created with percolators. The glass is made with a perfect artistic sense, and the technique is truly remarkable and fascinating. Wood and a thin piece of glass that is both slim and rigid are the first materials used in the bong’s construction. The water section is where construction begins, and in doing so, it also doubles as the main support and shape of the overall structure. The lengthy tube will first be warmed using the blowtorch as part of the process. As a result, the substance is let to grow into a sort of barrel-shaped object.

Expansion of the Construction

The inventor uses metal in the bong construction process to infuse oxygen into the heated component. As a result of this expansion, the balloon blows. You now know how are bongs made. They must blow things the same way with the tube’s twist to extend the bottom portion of the same to create it as needed. As the material continues to heat up, the designers will continue to work on the compartment until they get the desired shape and size of the model. After the container has been built, the individual makes sure to use the right tool to cut holes in the sides, and then the bong is finished.